The management of thermal loads and heat transfer is a critical factor in the design of many mechanical products and systems. Dynamiq Engineering provides a comprehensive Steady-State and Transient FEA Thermal Analysis & Design services using SolidWorks Simulation and ANSYS v13.0.

The management of thermal loads and heat transfer is a critical factor in the design of many mechanical products and systems. Dynamiq Engineering provides a comprehensive Steady-State and Transient FEA Thermal Analysis & Design services using SolidWorks Simulation and ANSYS v13.0.

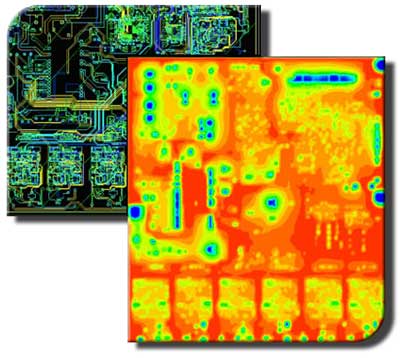

FEA Thermal Analysis allows the heat transfer into, out-of and through systems to be accurately modelled including the effects of:

* Conduction

* Convection

* Radiation

Dynamiq Engineering provides FEA thermal analyses and design optimisation to a wide variety of clients and industries, such as:

* Aerospace & Defence

* Electronic Systems

* Oil & Gas

* Heavy Industry

Typical applications include:

* PCB Design

* Heat Exchanger Design

* Heat Shield & Insulation Design & Optimisation

Once the temperature distribution has been computed then the effects of thermal expansion, thermal stress, fatigue, creep and thermally induced buckling can be calculated in detail. The FEA method allows effects such as temperature dependent properties, contact conditions and other sources of non-linearity to be modelled in detail, regardless of the complexity of the system.

Thermal analysis offers the ability to comprehensive, automated, multi-point optimisation of designs. This process allows engineers to automatically optimise a design to a given set of performance parameters and can be used to balance thermal loads, temperature distributions and heat transfer rates to given design targets.

Thermal Analysis & Design | Heat Transfer | Thermal Modelling | Fatigue | Creep | Optimisation