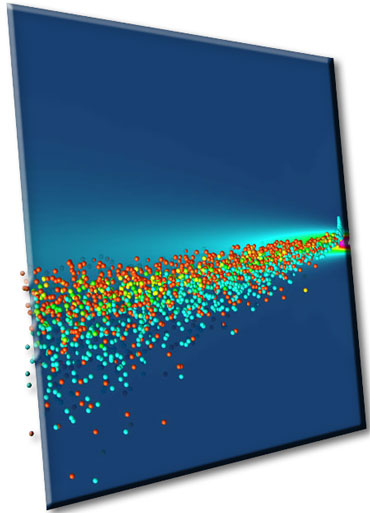

Multi-Phases flows involve combinations of solids, liquids and gases which interact. Typical applications involve sprays, solid particulate transport, state-changes, free surface flows, buoyancy problems and mixed species flows. CFD analysis provides a variety of modelling techniques for different classifications of common engineering multi-phase flows.

Multi-Phases flows involve combinations of solids, liquids and gases which interact. Typical applications involve sprays, solid particulate transport, state-changes, free surface flows, buoyancy problems and mixed species flows. CFD analysis provides a variety of modelling techniques for different classifications of common engineering multi-phase flows.

CFD analysis offers the ability to conduct comprehensive, automated, multi-point optimisation of designs. This process allows engineers to automatically optimise a design to a given set of performance parameters and can be used to optimise particle trajectories, or to control spray distributions or jet plumes to given performance targets.

Dynamiq Engineering provides all forms of multi-phase flow analyses ranging from simple particle tracking calculations for industrial applications through to comprehensive design and optimisation of spray equipment and fluid jets.

Typical applications include:

• Fluid Spray Design & Optimisation

• Fuel Injection Design & Optimisation

• Particulate Tracking & Concentration

• Free Surface Flows

• Mixed Species & Reacting Flows