Typical applications include:

• Nuclear Structures & Components

• Industrial Structures

• Aerospace Components

• Civil Structures

• Subsea Equipment

• Rail Components

• Marine Components

• Critical mechanical components

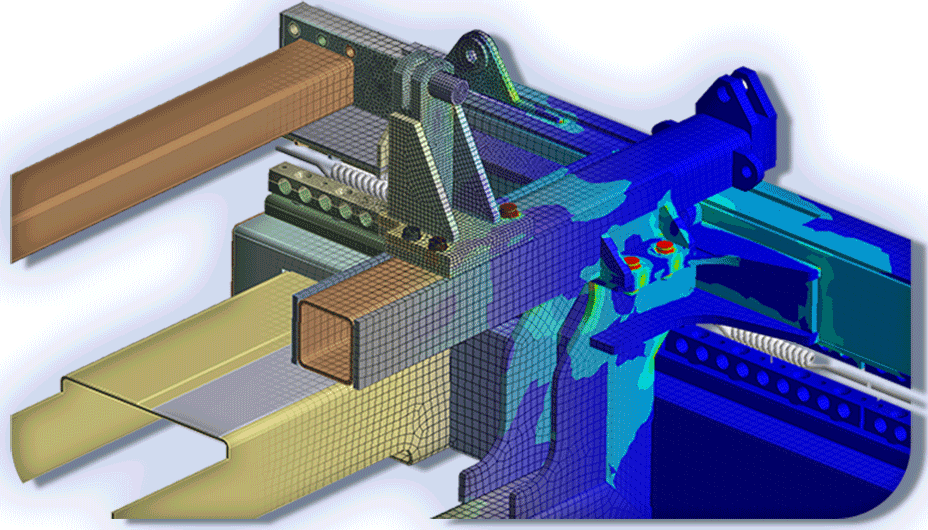

Using FEA to conduct Stress Analysis has many benefits over conventional hand calculation methods, the most significant of which is that the full structure is modelled, loaded and restrained as it would be in reality. FEA is able to simulate the distribution of the load, deflection and stress throughout the structure directly and is able to consider the complex effects of material, geometric and contact non-linearity. FEA Stress Analysis gives a full account of the performance, strength and stiffness of a structure rather than the somewhat limited details that are provided by hand calculations.

FEA based Stress analysis allows complex structural behaviour such as fatigue and creep to be comprehensively modelled and optimised effectively, in addition to dynamic loading conditions such as intermeshed gears, threads and wheel-rail problems.

The majority of practical FEA based Stress Analysis employs linear material models, with non linear contact, however Dynamiq offers the full range of capability including highly non-linear materials such as rubber and composites, complex contact and very large displacement problems. Dynamiq Engineering is also fully experienced in providing structural analysis using modern FEA methods to various structural codes (ISO, BS, ASCE, ASME, MIL). Conducting and reporting FEA based structural calculations to design codes that pre-date the widespread use of FEA is often challenging as the codes typcially set limit stress based on maximum reported values. FEA Stress analysis frequently reports singular stresses and very localised hotspots above the stated maxima which requires very careful handling by suitably qualified and experienced stress engineers.

Dynamiq Engineering provides over 150 stress analyses per year ranging from simple linear analysis of fabricated structures to advanced non-linear contact analysis of large mechanical assemblies. Dynamiq specialises in providing analysis and qualification reports for high integrity systems such as lifitng structures, automotive components, large bespoke fabricated structures , nuclear structures and aerospace structures. Dynamiq recently completed the FEA Stress Analysis on the worlds biggest tilting aluminium furnace and the worlds biggest peristaltic pump.

All of our analysis is completed in line with NAFEMS best practise and supported by extensive hand calculations and validation. Dynamiq also provides comprehensive Stress Hand Calculation Services to all relevant international standards.

For a no-obligation discussion of your requirements with an experienced stress engineer .

Stress Analysis | Stress Engineer | Static Stress | Buckling | Non-Linear | Transient Loads | Fatigue Analysis | Creep Analysis | Optimisation