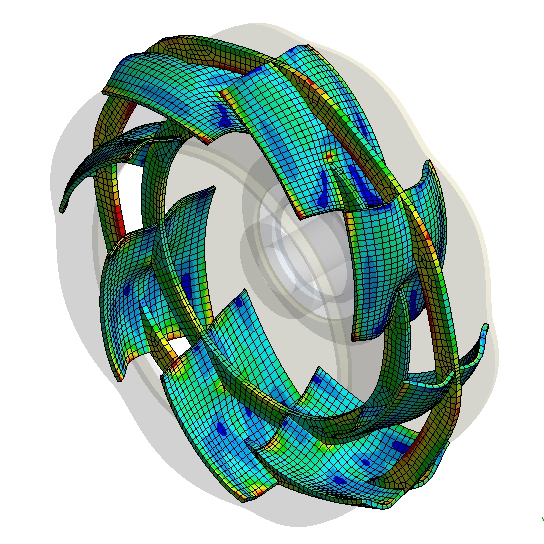

Finite Element Analysis (FEA), sometimes referred to as FE, or FEM, is a computer simulation technique that allows any product to be analysed in great detail to carry out a stress analysis, vibration analysis, heat transfer analysis and many other physical analyses.

Finite Element Analysis (FEA), sometimes referred to as FE, or FEM, is a computer simulation technique that allows any product to be analysed in great detail to carry out a stress analysis, vibration analysis, heat transfer analysis and many other physical analyses.

By using this technique, designers can verify that their products will conform to a client’s specifications early in the design cycle, greatly accelerating the product development process. Finite Element Analysis can be used to identify the cause of in-service failures of existing products and then deployed to design and optimise viable solutions within the constraints of the existing geometry.

FEA can significantly reduce product cost by eliminating unnecessary over-engineering allowing excess material to be removed or cheaper material grades to be employed. The level of insight and accuracy provided by modern FEA simulations greatly reduces companies’ exposure to technical risk and is sufficient

that far fewer physical prototypes are necessary, far less prototype testing is

required and hence the time-to-market and cost-to-market are both dramatically reduced.

Dynamiq is a member of NAFEMS, the international body for engineering analysis & simulation and conducts all types of FEA inline with industry best-practise guidelines using Solidworks Simulation and ANSYS v13.0.

Benefits of Finite Element Analysis Simulation include:

• Ability to accurately assess the performance & safety of any design prior to manufacture

• Identify and resolve design faults early

• Minimise cost of materials & maximise product performance.

• Speed up time to market

• Reduce development costs

Applications of Finite Element Analysis Services include:

• Stress Analysis (stress, strain, factors of safety, fatigue, creep)

• Vibration Analysis (modal, harmonic, random, transient dynamic)

• Thermal Analysis (conduction, convention, radiation, conjugate heat transfer)

• Seismic Analysis (equivalent static, response spectrum, transient dynamics)

• Impact & Crash Analysis (equivalent static, short duration explicit simulation)

Carrying out accurate and technically meaningful finite element analysis requires highly skilled and experienced specialists. Not only does Dynamiq Engineering provide finite element analysis using the worlds most advanced FEA software, but all of our technical staff are qualified to doctoral level and widely experienced. Crucially, as a technology development and engineering company, Dynamiq Engineering leverages the most advanced FEA techniques to provide real-world engineering outcomes that are practical, cost effective and commercially viable.

If your organisation requires specialist FEA Services, Design Troubleshooting, Product Qualification or independent finite element analysis of your products, Dynamiq Engineering has the expertise, resources and experience to meet your requirements.

For a no-obligation discussion of your requirements with one of our experienced experts,

|

|